Ejma Bellows Software Serial Numbers

Hi all, According with topic:, 'The difference between the large ID of the bellows and the small ID of the bellows will provide an area upon which the pessure will develop a compressive load on the nozzle.' So, It's the same method that we can find at EJMA Standards.

If we do a hand calculation (according with EJMA), it's possible to isolate the compressive load on the nozzle and the load that goes to pump anchor. But how I can simulate these loads isolated in CAESAR II?

And for API 610, what is the load used for calculations? Load on pump nozzle or Load on pump anchor? For a simple example, please use Example 06 encountered in EJMA Standards Appendix J, page J-19. Thanks in advance, Miyamoto Edited by Miyamoto ( 10/11/11 07:30 AM) #45257 - 10/13/11 06:17 AM Re: EJMA Hand Calculations x CAESAR II [] Member Registered: 09/13/11 Posts: 78 Loc: Brazil. Thanks danb and shr for these explanations.

Myheritage Family Tree Builder Premium Keygen Generator Letöltés on this page. Ejma Bellows Software Engineer. Adds checksums to Serial Numbers and Activation Codes so typographical errors will be rejected. Various small bug fixes.

But, according to EJMA these loads acting on pump nozzle is less than acting on pump anchor. So, how can I simulate in CAESAR II the load that goes only to nozzle (for API 610, is this important load?). If we model a pump nozzle as a restraint ANC, the load resultant is thrust load, and if we use this force to compare with API 610 allowables, we will commit a mistake due API 610 verify only loads on the nozzle. Danb, but if the load acting in pump casing is bigger than nozzle, this load will be response for shaft misalignment, am I right? So, I have 2 options: 1) I do hand calculations as shown in EJMA for pump nozzle loads and use analysis module of CAESAR with these loads. 2) Simulate only the load on pump nozzle (desconsidering as ANC) What I need to do?

Regards, Miyamoto Edited by Miyamoto ( 10/27/11 06:08 AM) #45519 - 10/27/11 06:30 AM Re: EJMA Hand Calculations x CAESAR II [] Member Registered: 04/22/05 Posts: 1256 Loc. If you want an API 610 check, fine, you can do manually or you can apply a force in opposition with your thrust in order to emulate the effective load on the nozzle. Alternatively you can do as follows. Do not fill in the “Effective ID” field then calculate the real force on the nozzle and insert it in the “Force/moments” field.

However you will be responsible for the fact that you apply a thrust on the pump case. If the pump vendor is informed and accept this, fine. If not, do not use untied bellows. Note the force in Anchor A from your example. Hope I've made myself clear. My last doubt. What matter for vendor or API 610 check?

Effective load on the nozzle as show EJMA Example? Or thrust load applied on pump case/anchor? Only for understand: API and vendor don't evaluate force on case/anchor? It means don't matter if nozzle checked by API was ok and load on pump case is overloaded? If this is all right, how can I eliminate thrust forces in a straight pipe considering a set of pumps in series(begin as discharge and end of pipe as suction of another pump)? Thanks again, Miyamoto #45522 - 10/27/11 08:46 AM Re: EJMA Hand Calculations x CAESAR II [] Member Registered: 04/22/05 Posts: 1256 Loc. Hi all again, Sorry for ressurrect an old thread, but I have doubts about this subject yet.

Using an untied bellow, according to EJMA, the load aplied at pump nozzle is different of the load that aplied at pump anchor (this is the thrust force). And API 610 Standard, Table 5 show allowables to compare with the model. What load I use to compare to API 610? Load at nozzle or load at pump anchor?

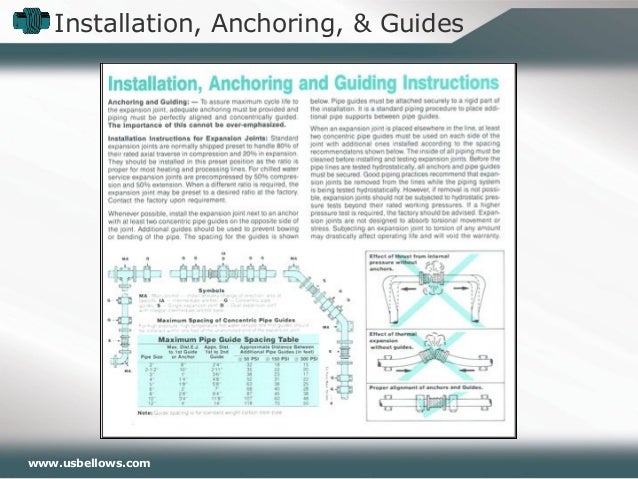

Best Regards, (And sorry again) Miyamoto #46806 - 01/17/12 10:11 AM Re: EJMA Hand Calculations x CAESAR II [] Member Registered: 09/13/11 Posts: 78 Loc: Brazil. Hi Miyamoto, There is a pressure thrust exist in tied expansion joint also, but that presusre thrust is taken care by the tie rods, so generally it woun't have any effect on your calcualtion. Tie Rods: - are the devices which usually in the form of rods or bars, attached to the expansion joint assembly whose primary function is to continuously restrain the full pressure thrust during normal operation while permitting only lateral deflection. Angular rotation can be accommodated only if two tie rods are used and located 90 degrees opposed to the direction of rotation.

I hope this will help you!! Regards, R.K.

#46834 - 01/19/12 03:57 AM Re: EJMA Hand Calculations x CAESAR II [] Member Registered: 09/29/07 Posts: 602 Loc: Romania. For piping systems that contain no expansion joints, the axial loads include a longitudinal force calculated as Pressure X Internal Pipe Area. Reporting this force to the pipe cross-sectional area, you obtain the stress due to pressure load, usually counted as 'PD/4t'.

In 'EJ with no rods' case or in case the rods are not working, the EJ 'breaks' the piping system in two parts and the pressure thrust is acting on both of them. I suggest you to see also You can find there a sketch for Peng's book. In fact, there is an warning that the existence of roads is not always a guarantee. As you can see, Mr. Peng made a suggestion on the piping part. #46838 - 01/19/12 06:36 AM Re: EJMA Hand Calculations x CAESAR II [] Member Registered: 09/29/07 Posts: 602 Loc: Romania. Obviously, I must say 'the existence of rods is not always a guarantee'.

Peng point is that the pressure thrust will move the piping on the sliding support, reestablishing the 'piping continuity' thru 'tie-rods'. Of course, it is a good idea. However, in my understanding, when there is a pressure thrust moving the piping (as in book's sketch), it means that there is also a coincidental pressure thrust acting on Pump side. Of course, on that side the force is not moving the pump.however, theoretically, this short-time force is anyway acting on pump.

But is only a short-time force, until the rods are working again; in addition this 'process' is smooth enough. Just my opinion, of course. #46846 - 01/19/12 08:38 AM Re: EJMA Hand Calculations x CAESAR II [] Member Registered: 12/12/09 Posts: 38 Loc: TX, US. The discussion in Peng’s book assumes using an EJ to solve the equipment load problem due to piping thermal expansion. Peng criticism is addressed to the fact 'The anchor is so important in the application of bellow expansion joints that many engineers seem to automatically place an anchor or anchors in an expansion joint installation.' Because the anchor point does not move, the pipe located between the anchor and equipment expands into the joint. This leaves the nuts loose with gaps.

So you have now other problem: 'when tie-rods become loose, they no longer resist the pressure thrust force.' Peng conclusion is 'The correct installation is to allow the support point to slide as shown. The movement of the elbow ensures the tightness of the tie-rods, because the pressure keeps pushing the elbow until the rods are tight.

The tightened tie-rods can then absorb the bellow pressure thrust force, leaving no unbalanced pressure thrust force on the machine.' My comment was that things are not so simple, because-theoretically- 'the pressure keeps pushing the elbow' is coincident with 'the pressure keeps pushing the equipment casing'. When you have an anchor attached to elbow, this fact is evident and you have a long-time negative effect of pressure. In my understanding, when you have an sliding support there, this effect still exists but is likely to be a short-time state if the pressure trust can easily move the piping on sliding support. In this case the developed nuts' 'gap' would be quite small and smoothly compensated by the pressure trust force. But the real behavior (and actual gap) depends on pressure thrust magnitude, friction effects and stiffness of the piping you expect to move. Best regards.

In order to understand what I'm saying, I attached the sketch previously posted Attachments (487 downloads).

Fluidyne design and manufacture Metal Bellows Type Expansion Joint in heat resistant and non-ferrous alloys of nominal bore ranging from 20mm I.D. To 1500mm O.D. Fluidyne follows EJMA standards for their design, manufacture and quality assurance of metal bellows. The designs are validated with the test equipments available in-house. In addition to bellows, Fluidyne has developed non-circular racetrack cross-section bellows for UHV application.

Fluidyne has also localized the manufacture of welded diaphragm bellows. These Diaphragm Bellows are used in Atomic Power Stations, Robotics, Aerospace Industries and Instrumentation. Fluidyne takes pride in the fact that no other firm in India has been able to develop these special Bellows till date.

When it comes to the design and development of Bellows, Fluidyne has carved a niche in the minds of users regarding their capabilities and willingness to experiment in the new fields and for development.